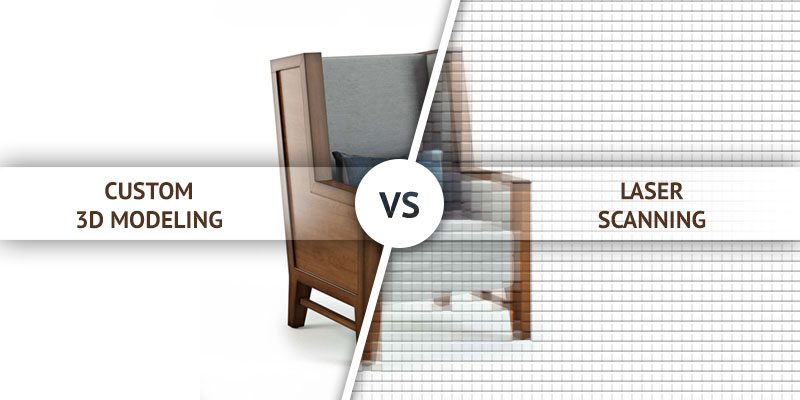

When searching for an impactful 3D Solution for your products or services, you will have to choose the right way of creation of 3D Models. Just 10 years ago, the automated way of 3D Models creation simply didn’t exist. Nowadays, in contrast, there are two options available – Custom 3D Modeling and Laser Scanning.

Custom 3D Modeling and Laser Scanning are often perceived as competitors. Both technologies seem to have the same goals and therefore look interchangeable. As a result, one often wonders what to choose when looking for 3D Modeling services.

It is certainly true that the spheres of influence of Custom 3D Modeling and 3D Scanning overlap. However, are they exactly the same? To answer the question, let’s have a closer look at both.

Laser Scanning

Laser scanning is a process of 3D data collection by passing of a laser line over the surface of a certain object or environment. The process is performed with a laser scanner, equipped with a special sensor capturing the information on the exact shape and size. Particularly advanced laser scanners can even perceive the information about color. Most noteworthy, it works by registering 3D points in space, so the information is highly accurate and comes in form of “data cloud”. Afterwards, the data received is processed on computer to receive the final result.

Types of Technologies used for 3D Scanning

3D scanning can be based on different technologies:

- Laser triangulation

- Structured light

- Photogrammetry

- Contact

- Laser pulse

As for the diversity of tools, 3D scanners come in 3 main types:

- laser line

- patch

- spherical

3D scanning is a good way to create three-dimensional representations of environments and objects with complex geometry. It allows to create a CAD model with which one can easily work afterwards. For instance, the 3D model received can be altered and, after computer processing, 3D printed.

It is therefore well-suited for detecting the weak and strong sides of the existing product design. As well as that, 3D scanning is used to recreate the existing designs, improve them, test the quality of the objects, manufacture fashion and health care products, and even to create 3D models of the buildings.

Moreover, 3D scanning is predicted to change the future of tailor clothing creation. It will enable tailors to create virtual dressing rooms equipped with 3D scanners. The clients enter the rooms to be 3D scanned there and give the most accurate measurements of their bodies. Owing to this, the tailor will create bespoke suits and dresses that will make customers look like a million dollars.

The Spheres of Use

Laser scanning is widely used in Aeronautics, Reverse Engineering, Dental, Jewelry, Video Games, Animation and Special Effects.

Advantages of 3D Scanning

- less time for collecting data

- easy procedure of gathering the information

- precision of result

Take your design presentation to a new level with interior rendering

Custom 3D Modeling

As for the general Technology of 3D Modeling, you can learn about it in detail from another of our articles.

Custom 3D modeling is the process of computerized creation of a 3D form of an object, existent or non-existent. It is performed by a 3D artist using 3D Modeling software. This way, the result depends on the manual skill of your CG artist. Let’s focus on each of those cases separately.

Custom 3D Modeling for Real Objects

The main advantage is that one doesn’t need any contact with the object reproduced to create the replica. The reason is that all the necessary calculations will be performed by computer. And that is a tangible advantage. Let’s imagine that you are a major interior designer with strong international reputation, working on a project located in Europe. The problem is that your office is situated in the USA. As a result, you have two choices here. You can either embark on a plane and go there, or gather all the data from the clients and have a custom 3D model of the location done. Unless you particularly fancy visiting a country and have loads of free time, second is usually the case.

Some believe that Laser Scanning is faster than Custom 3D Modeling. However, this is arguable. The problem with that theory is that Laser Scanning doesn’t narrow down to collection of data, which is fast indeed. The 3D Model created needs some further work on it. And if you add the time all logistics take, for instance, to go to Europe, you’ll realize that it’s far from the truth.

Custom 3D Modeling for Virtual Objects

Another special feature of the 3D modeling lies in the fact that it gives the possibility to create the things that have not been created yet. For instance, the building that exists only in form of the project. Owing to 3D modeling, the developer can show it in all its complexity and beauty to the potential investors. Moreover, it is used for Product Prototyping to test the product design without actually manufacturing it. This way, producer alleviates the risks of losing his investment on unpopular products and designs.

The Spheres of Use

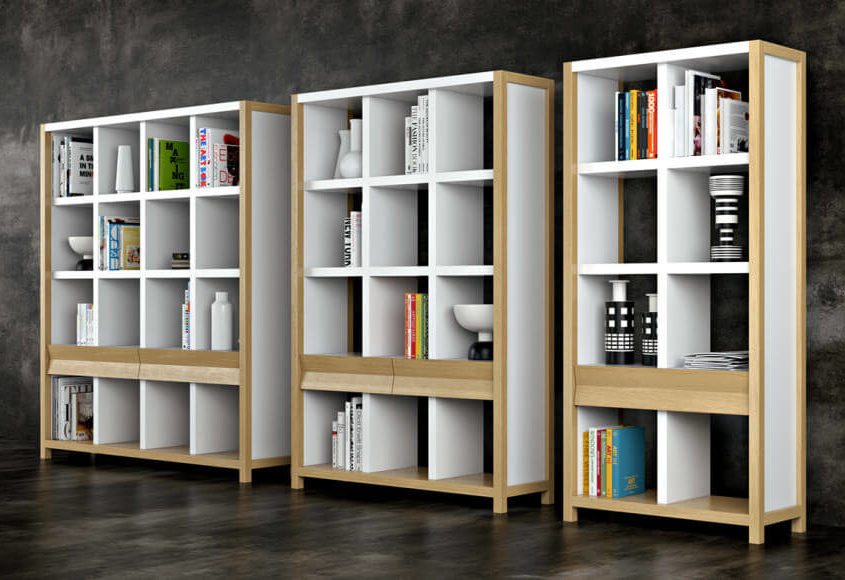

Custom 3D Modeling is widely used in Entertainment, Video Games, Advertising, Web Design, Marketing, Architecture, Interior Design, Real Estate, Science and many others.

Advantages of Custom 3D Modeling

- possibility of creating 3D Models of non-existent objects

- no need to travel to collect the data

- possibility to test the product demand without manufacturing it

- incredible design opportunities

Showcase your architectural project like a true work of art, brought to life with cutting-edge AI-powered CGI technology.

As a conclusion, the main difference between 3D modeling and Laser Scanning is that they are good at different things. 3D scanning, for instance, is excellent at gathering large amounts of data on complex objects for different purposes. If the object or environment is not available or doesn’t exist yet, Custom 3D Modeling is the best choice. As for the time spent, it varies according to the project. If Laser Scanning gathers data really fast, Custom 3D Modeling saves you time you’d normally spend on journeys.

If you are looking for high quality 3D models, contact ArchiCGI rendering company. Our managers will find the best 3D solution for you and will take care of your project, and its quality will exceed all expectations. Start working with us now and try our Test Drive option!

Catherine Paul

Content Writer, Editor at ArchiCGI

Catherine is a content writer and editor. In her articles, she explains how CGI is transforming the world of architecture and design. Outside of office, she enjoys yoga, travelling, and watching horrors.

Comments

James

Elijah